The

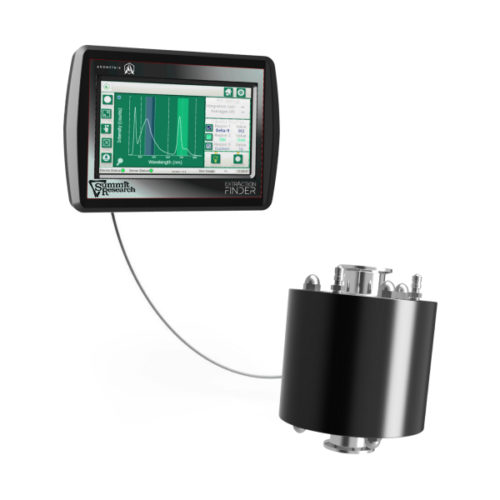

Sensor Ultra Sensitive features the brand new, ultra-sensitive sensor. This package is unique in that - not only does it serve distillation and extraction processes - but also serves

Chromatography,

Conversion Reaction, and other processes that require more extreme detection. For certain processes, highly sensitive process monitoring is essential. Generally speaking, the more solvent involved in the process means the more sensitive the sensor needs to be. With that in mind, the ULTRA was created.

If you are an existing customer, you have the option to

upgrade to a standalone ULTRA Sensor for $1,350. Please call us for more details.

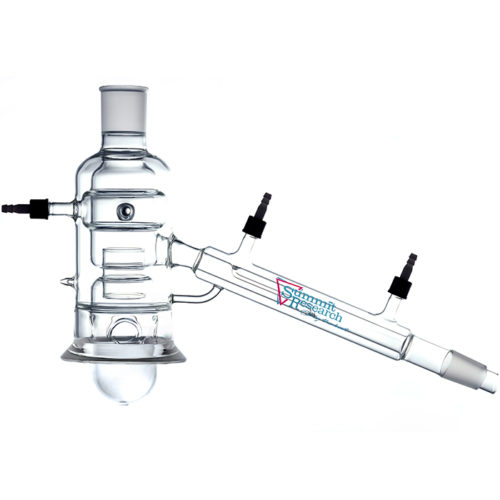

Use this sensor on any chromatography column with the

GL18 to #34 adapter.

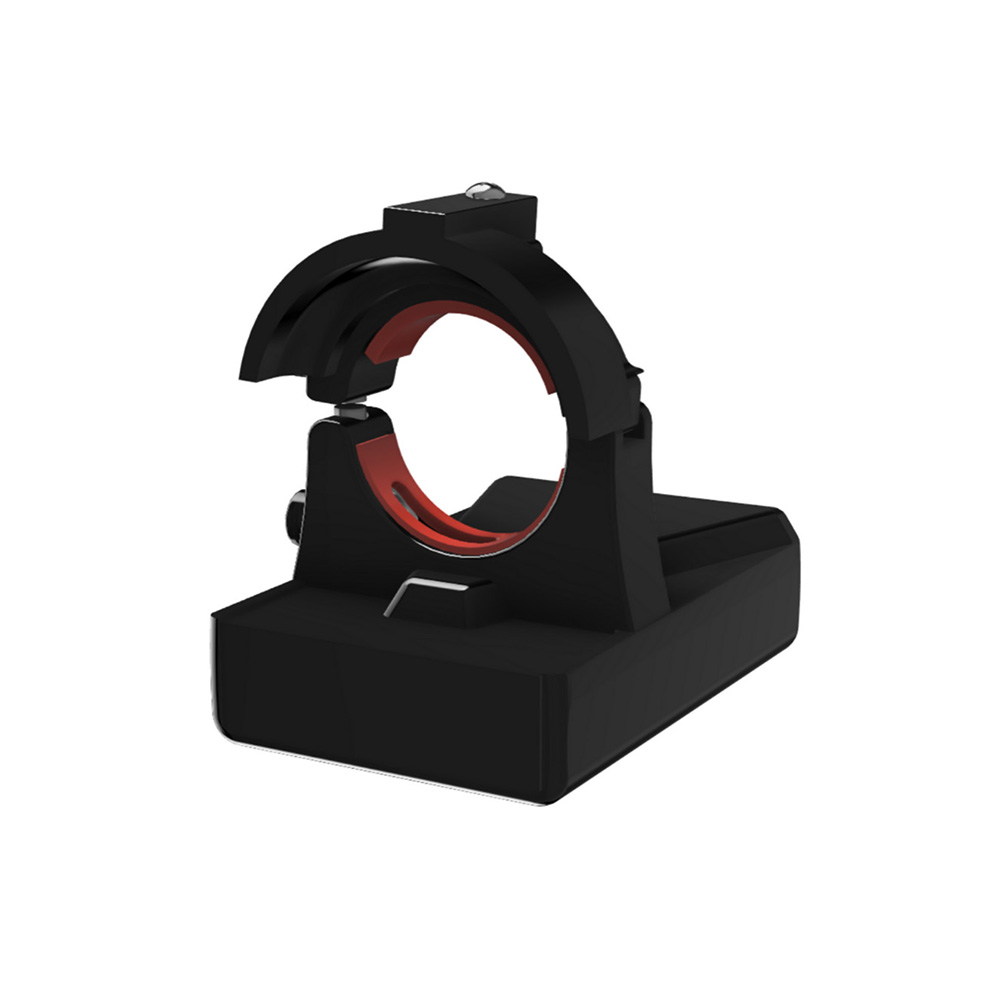

The Fraction Finder Sensor 34/45 consists of an optical light pulse and detector, acting as “the eyes” of the system. It wraps around a distillation/chromatography setup tube and connects to the Fraction Finder display to track important data on the process.

- Fraction Finder optical sensor with ultra-sensitive detector

- Magnetic locking mechanism

- Anodized aluminum apertures

- 90° strap rotation

- Currently only available in size 34mm

- Validated by Arometrix for use on distillation systems

- Currently being tested on reverse-phase chromatography processes

- Display and sight glass not included

Information common with all Fraction Finder sensors

These sensors are black for a reason:

- Black absorbs all light while blocking out ambient light.

- This leads to better signaling and the most valid data possible transmitting to the Fraction Finder display.

- For example, a white sensor wouldn’t work because it would reflect the light into your glassware and into the sensor, harming the reading.

Chemical Resistant

- This reduces any degradation from solvents, crude oils, extracts, etc..

- This protects the sensor and ensures that it lives to see an endless amount of runs.

Thermo Resistant / Safety

- The black coating we use on each sensor is a high temperature, thermal resistant coating, it can withstand temperatures well above anything you’d see in a distillation lab.

- It’s nearly impossible to set one of our sensors on fire, the coating is almost completely fireproof!

- This protects the user, the equipment, and (in worst case scenarios) the entire lab.

Sensor only, monitor and accessories not included.