$13,500.00

A BINDER safety vacuum drying oven ensures maximum safety when drying organic solvents standard with TÜV/GS. The inner chamber of the VDL safety vacuum drying oven is designed according to ATEX guidelines 2014/34/EU Ex II 3/-G Ex h IIB T1-T3 Gc X.Benefits

Important characteristics

| Performance Data Temperature | |

| Heating-up time to 100 °C [min] | 80 |

| Temperature fluctuation [± K] | 0.1 |

| Temperature range 15 °C above ambient temperature to [°C] | 200 |

| Temperature variation at 100 °C [± K] | 2 |

| Vacuum Data | |

| Leak rate [bar/h] | 0.01 |

| Permitted end vacuum [mbar] | 0.01 |

| Electrical data | |

| Nominal power [kW] | 1.2 |

| Phase (Nominal voltage) | 1~ |

| Power frequency [Hz] | 50/60 |

| Rated Voltage [V] | 230 |

| Unit fuse [A] | 10 |

| Connections | |

| Compressed air connection for pressure-encapsulation | 8 mm |

| Inert gas connection with flow limiter (RP") | 3/8 |

| Measuring access port with small flange [DN mm] | 16 |

| Vacuum connection with small flange [DN mm] | 16 |

| Housing dimensions not incl. fittings and connections | |

| Depth net [in] | 21.67 |

| Height net [in] | 30.53 |

| Width net [in] | 25.02 |

| Internal Dimensions | |

| Depth [in] | 13.4 |

| Height [in] | 15.76 |

| Width [in] | 15.76 |

| Measures | |

| Interior volume [cu.ft.] | 1.9 |

| Load per rack [lbs] | 44 |

| Net weight of the unit (empty) [lbs] | 209 |

| Permitted load [lbs] | 99 |

| Viewing window height [in] | 12.1 |

| Viewing window width [in] | 13.79 |

| Wall clearance back [in] | 3.94 |

| Wall clearance sidewise [in] | 5.32 |

| Fixtures | |

| Number of shelves (std./max.) | 2/5 |

-

All technical data is specified for unloaded units with standard equipment at an ambient temperature of +22 °C ±3 °C and a power supply voltage fluctuation of ±10%. The temperature data is determined in accordance to BINDER factory standard following DIN 12880, observing the recommended wall clearances of 10 % of the height, width, and depth of the inner chamber. All indications are average values, typical for units produced in series. We reserve the right to change technical specifications at any time.

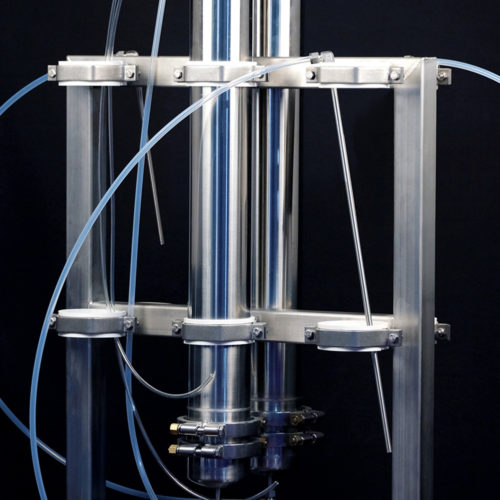

To purchase, please contact Summit Research at 831-226-2948 or by eMail. Items ship 1-3 days after orders have been processed unless otherwise specified. Price does not include shipping and will be included in your final estimate before processing.

To purchase, please contact Summit Research at 831-226-2948 or by eMail. Items ship 1-3 days after orders have been processed unless otherwise specified. Price does not include shipping and will be included in your final estimate before processing.

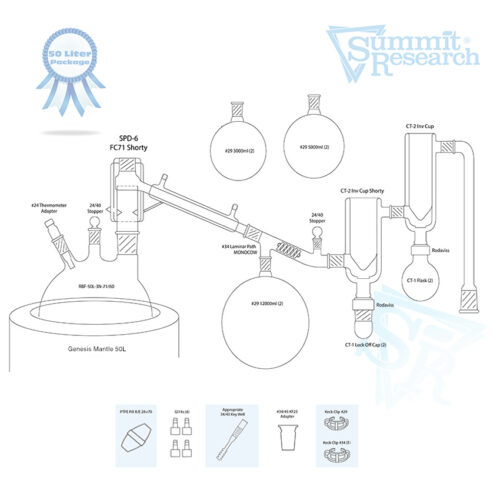

Clamps, stands and glassware in example picture not included. 4.75 inch triclamp clamp and o-ring not included.

Patented SS Cold Trap Accelerator available only here at Summit Research.

Clamps, stands and glassware in example picture not included. 4.75 inch triclamp clamp and o-ring not included.

Patented SS Cold Trap Accelerator available only here at Summit Research.