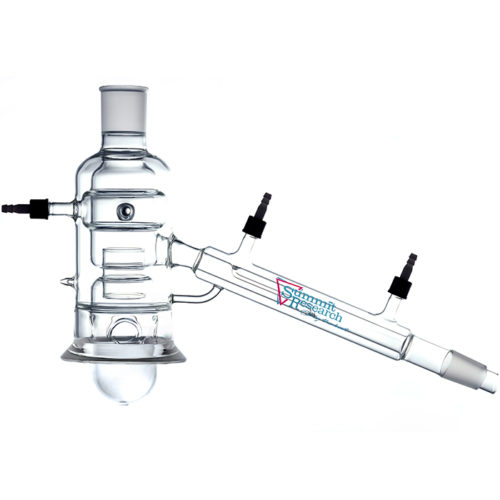

The new SPD-8 Series Heads (FC55, 100mm, 150mm) bring a fraction collecting core combined with condenser coil. If you want absolute temperature control in a head, look no further. With these types of heads, if you dip the coil temp down it will act as a violent collection of molecules dragged to the coil like a magnet. That coil would inherently distribute those lower temps right on the surface of the fraction collector dish and that would display a whole new set of efficiency within the head. All Short Path Distillation 8 Heads have a 45/50 thermoport and a 34/45 discharge arm.

Short Path Distillation 8 Head in use at the lab:

Instagram Demo

The condenser in this 55/50 head absorbs as much heat as possible and removes BTU energy from the vapor prior to entering the condenser arm. This allows the vacuum jacketed head to operate like it’s supposed to. The coil in the head doesn’t disturb molecular flow dynamics as it’s duty is to absorb heat before the heat affects the sides of the walls of the fraction collector as well as allows those ambient vacuum void temps to be more stable. When you get blow by in a head it means it’s just working overtime because the arm sends back fluids to the heater chiller and it can’t maintain the BTU heat removal. So if you can maintain exact temps you can bounce unwanted fractions right out of the condenser arm without over shooting flow rates. This maintains a drier vacuum in the condenser arm.

45 Key Well, 45 Well Stopper and GL18s (4) included.

As always, Summit uses 100% best quality glass blanks that are THICKER and built BEYOND STANDARDS made right here in the USA. Our glassware is made specifically for efficiency and durability. Summit provides the quality of lab equipment that you deserve to streamline your short path distillation process.

Summit recommends all users of any and all glassware to operate inside a ventilated fume hood with sufficient blast shields to prevent injury in case of fatigued glass failure. Summit is not responsible or liable for the result of any failures from use, and/or loss of subsequent hardware contamination/failure with or without the result of material loss or damaged caused to surroundings. By purchasing our premiere lines of laboratory glassware the user is responsible to operate in the recommended environment safely. We recommend all users to operate in a legal and licensed facility where safety is the number 1 goal. Short Path Distillation 8 Head FC55