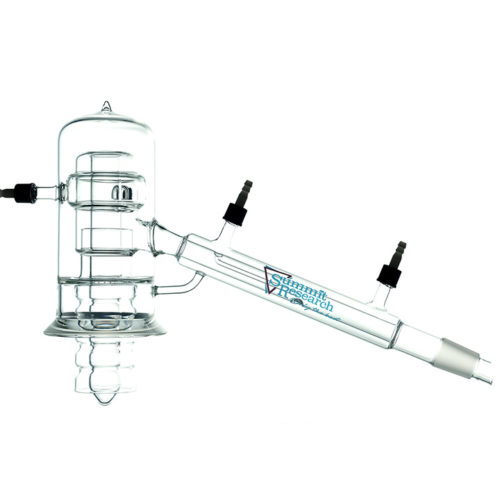

$4,499.99

The HB Series Halo heads are inspired by our original fraction collector technology and have taken theses concepts to a new level. Halo technology allows for liquid temperature modulation at the top the head, dialing in your temps at a point in your short path distillation never before achieved. See the Halo in action: Instagram Demo-

100mm clamp, O-ring and PTFE GL18s (4) included. Has 34/45 discharge port with built in key. Our 100mm heads fit exclusively to Summit flanged boiling flasks:

As always, Summit uses 100% best quality glass blanks that are THICKER and built BEYOND STANDARDS made right here in the USA. Our glassware is made specifically for efficiency and durability. Summit provides the quality of lab equipment that you deserve to streamline your short path distillation process.

Summit recommends all users of any and all glassware to operate inside a ventilated fume hood with sufficient blast shields to prevent injury in case of fatigued glass failure. Summit is not responsible or liable for the result of any failures from use, and/or loss of subsequent hardware contamination/failure with or without the result of material loss or damaged caused to surroundings. By purchasing our premiere lines of laboratory glassware the user is responsible to operate in the recommended environment safely. We recommend all users to operate in a legal and licensed facility where safety is the number 1 goal. Short Path Distillation Head HB1 Halo 100

To purchase, please contact Summit Research at 831-226-2948 or by eMail. Items ship 1-3 days after orders have been processed unless otherwise specified. Price does not include shipping and will be included in your final estimate before processing.

100mm clamp, O-ring and PTFE GL18s (4) included. Has 34/45 discharge port with built in key. Our 100mm heads fit exclusively to Summit flanged boiling flasks:

As always, Summit uses 100% best quality glass blanks that are THICKER and built BEYOND STANDARDS made right here in the USA. Our glassware is made specifically for efficiency and durability. Summit provides the quality of lab equipment that you deserve to streamline your short path distillation process.

Summit recommends all users of any and all glassware to operate inside a ventilated fume hood with sufficient blast shields to prevent injury in case of fatigued glass failure. Summit is not responsible or liable for the result of any failures from use, and/or loss of subsequent hardware contamination/failure with or without the result of material loss or damaged caused to surroundings. By purchasing our premiere lines of laboratory glassware the user is responsible to operate in the recommended environment safely. We recommend all users to operate in a legal and licensed facility where safety is the number 1 goal. Short Path Distillation Head HB1 Halo 100

To purchase, please contact Summit Research at 831-226-2948 or by eMail. Items ship 1-3 days after orders have been processed unless otherwise specified. Price does not include shipping and will be included in your final estimate before processing. -

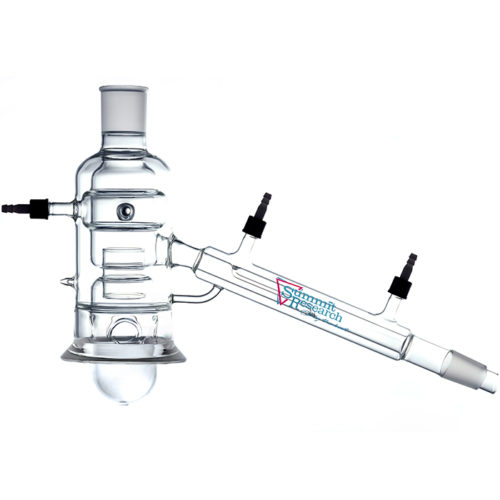

$4,299.99

The HB Series Halo heads are inspired by our original fraction collector technology and have taken theses concepts to a new level. Halo technology allows for liquid temperature modulation at the top the head, dialing in your temps at a point in your short path distillation never before achieved. See the Halo in action: Instagram Demo 34/45 key, 100mm clamp with O-ring and PTFE GL18s (4) included. 34/45 discharge port. Our 100mm heads fit exclusively to Summit flanged boiling flasks:

As always, Summit uses 100% best quality glass blanks that are THICKER and built BEYOND STANDARDS made right here in the USA. Our glassware is made specifically for efficiency and durability. Summit provides the quality of lab equipment that you deserve to streamline your short path distillation process.

Summit recommends all users of any and all glassware to operate inside a ventilated fume hood with sufficient blast shields to prevent injury in case of fatigued glass failure. Summit is not responsible or liable for the result of any failures from use, and/or loss of subsequent hardware contamination/failure with or without the result of material loss or damaged caused to surroundings. By purchasing our premiere lines of laboratory glassware the user is responsible to operate in the recommended environment safely. We recommend all users to operate in a legal and licensed facility where safety is the number 1 goal. Short Path Distillation Head HB2 Halo 100

To purchase, please contact Summit Research at 831-226-2948 or by eMail. Items ship 1-3 days after orders have been processed unless otherwise specified. Price does not include shipping and will be included in your final estimate before processing.

34/45 key, 100mm clamp with O-ring and PTFE GL18s (4) included. 34/45 discharge port. Our 100mm heads fit exclusively to Summit flanged boiling flasks:

As always, Summit uses 100% best quality glass blanks that are THICKER and built BEYOND STANDARDS made right here in the USA. Our glassware is made specifically for efficiency and durability. Summit provides the quality of lab equipment that you deserve to streamline your short path distillation process.

Summit recommends all users of any and all glassware to operate inside a ventilated fume hood with sufficient blast shields to prevent injury in case of fatigued glass failure. Summit is not responsible or liable for the result of any failures from use, and/or loss of subsequent hardware contamination/failure with or without the result of material loss or damaged caused to surroundings. By purchasing our premiere lines of laboratory glassware the user is responsible to operate in the recommended environment safely. We recommend all users to operate in a legal and licensed facility where safety is the number 1 goal. Short Path Distillation Head HB2 Halo 100

To purchase, please contact Summit Research at 831-226-2948 or by eMail. Items ship 1-3 days after orders have been processed unless otherwise specified. Price does not include shipping and will be included in your final estimate before processing. -

$9,630.49

Rebuilt Edwards E2M40 + Blower (mechanical booster) All air cooled dual stage Rotary Vane Pump, 208 V, 50 Hz/208-230 V, 60 Hz/460 V, 60 Hz, Three Phase with KF-40 inlet to blower. Edwards E2M series two stage oil sealed rotary vane vacuum pumps are renowned for their high ultimate vacuum, rapid pumping speeds, quiet operation and ability to handle water vapor. These direct drive rotary vane pumps are inherently compact and vibration free. Blowers add a dimension of vacuum that tops most dual pump options. Mechanical boosters feature the unique hydro-kinetic drive that provides pump down times cut by 50%, when compared with direct drive pumps, no bypass lines or pressure switches required, universal voltage motors, reduced capital and operating costs, air cooled motors – with water cooled options, and quiet, minimum vibration. Operating at relatively low pressures, the mechanical booster pump is not exposed to the same concentrations of corrosive process media as is the backing pump, which makes it highly reliable. Comes with Pump, Blower, MF100 filter and I 19 Standard fluid. To purchase, please contact Summit Research at 831-226-2948 or by eMail. Items ship 1-3 days after orders have been processed unless otherwise specified. Price does not include shipping and will be included in your final estimate before processing. -

$12,500.00

A BINDER safety vacuum drying oven ensures maximum safety when drying organic solvents standard with TÜV/GS. The inner chamber of the VDL safety vacuum drying oven is designed according to ATEX guidelines 2014/34/EU Ex II 3/-G Ex h IIB T1-T3 Gc X.Benefits

Important characteristics

To purchase, please contact Summit Research at 831-226-2948 or by eMail. Items ship 1-3 days after orders have been processed unless otherwise specified. Price does not include shipping and will be included in your final estimate before processing.-

All technical data is specified for unloaded units with standard equipment at an ambient temperature of +22 °C ±3 °C and a power supply voltage fluctuation of ±10%. The temperature data is determined in accordance to BINDER factory standard following DIN 12880, observing the recommended wall clearances of 10 % of the height, width, and depth of the inner chamber. All indications are average values, typical for units produced in series. We reserve the right to change technical specifications at any time.

-

-

$13,500.00

A BINDER safety vacuum drying oven ensures maximum safety when drying organic solvents standard with TÜV/GS. The inner chamber of the VDL safety vacuum drying oven is designed according to ATEX guidelines 2014/34/EU Ex II 3/-G Ex h IIB T1-T3 Gc X.Benefits

Important characteristics

Performance Data Temperature Heating-up time to 100 °C [min] 80 Temperature fluctuation [± K] 0.1 Temperature range 15 °C above ambient temperature to [°C] 200 Temperature variation at 100 °C [± K] 2 Vacuum Data Leak rate [bar/h] 0.01 Permitted end vacuum [mbar] 0.01 Electrical data Nominal power [kW] 1.2 Phase (Nominal voltage) 1~ Power frequency [Hz] 50/60 Rated Voltage [V] 230 Unit fuse [A] 10 Connections Compressed air connection for pressure-encapsulation 8 mm Inert gas connection with flow limiter (RP") 3/8 Measuring access port with small flange [DN mm] 16 Vacuum connection with small flange [DN mm] 16 Housing dimensions not incl. fittings and connections Depth net [in] 21.67 Height net [in] 30.53 Width net [in] 25.02 Internal Dimensions Depth [in] 13.4 Height [in] 15.76 Width [in] 15.76 Measures Interior volume [cu.ft.] 1.9 Load per rack [lbs] 44 Net weight of the unit (empty) [lbs] 209 Permitted load [lbs] 99 Viewing window height [in] 12.1 Viewing window width [in] 13.79 Wall clearance back [in] 3.94 Wall clearance sidewise [in] 5.32 Fixtures Number of shelves (std./max.) 2/5 Further information (Data Sheets, Operating Manuals and Technical Drawings) can be downloaded from BINDER. A Basic vacuum oven diagram can be seen/downloaded here:-

All technical data is specified for unloaded units with standard equipment at an ambient temperature of +22 °C ±3 °C and a power supply voltage fluctuation of ±10%. The temperature data is determined in accordance to BINDER factory standard following DIN 12880, observing the recommended wall clearances of 10 % of the height, width, and depth of the inner chamber. All indications are average values, typical for units produced in series. We reserve the right to change technical specifications at any time.

To purchase, please contact Summit Research at 831-226-2948 or by eMail. Items ship 1-3 days after orders have been processed unless otherwise specified. Price does not include shipping and will be included in your final estimate before processing.

To purchase, please contact Summit Research at 831-226-2948 or by eMail. Items ship 1-3 days after orders have been processed unless otherwise specified. Price does not include shipping and will be included in your final estimate before processing. -

-

$17,500.00

A BINDER safety vacuum drying oven ensures maximum safety when drying organic solvents standard with TÜV/GS. The inner chamber of the VDL safety vacuum drying oven is designed according to ATEX guidelines 2014/34/EU Ex II 3/-G Ex h IIB T1-T3 Gc X.Benefits

Important characteristics

Performance Data Temperature Heating-up time to 100 °C [min] 95 Temperature fluctuation [± K] 0.1 Temperature range 15 °C above ambient temperature to [°C] 200 Temperature variation at 100 °C [± K] 3.5 Vacuum Data Leak rate [bar/h] 0.01 Permitted end vacuum [mbar] 0.01 Electrical data Nominal power [kW] 1.9 Phase (Nominal voltage) 1~ Power frequency [Hz] 50/60 Rated Voltage [V] 230 Unit fuse [A] 10 Connections Compressed air connection for pressure-encapsulation 8 mm Inert gas connection with flow limiter (RP") 3/8 Measuring access port with small flange [DN mm] 16 Vacuum connection with small flange [DN mm] 16 Housing dimensions not incl. fittings and connections Depth net [in] 26.4 Height net [in] 35.46 Width net [in] 29.16 Internal Dimensions Depth [in] 18.12 Height [in] 19.94 Width [in] 19.94 Measures Interior volume [cu.ft.] 4.1 Load per rack [lbs] 44 Net weight of the unit (empty) [lbs] 337 Permitted load [lbs] 143 Viewing window height [in] 16.27 Viewing window width [in] 17.97 Wall clearance back [in] 3.94 Wall clearance sidewise [in] 5.32 Fixtures Number of shelves (std./max.) 2/6 Further information (Data Sheets, Operating Manuals and Technical Drawings) can be downloaded from BINDER. A Basic vacuum oven diagram can be seen/downloaded here:-

All technical data is specified for unloaded units with standard equipment at an ambient temperature of +22 °C ±3 °C and a power supply voltage fluctuation of ±10%. The temperature data is determined in accordance to BINDER factory standard following DIN 12880, observing the recommended wall clearances of 10 % of the height, width, and depth of the inner chamber. All indications are average values, typical for units produced in series. We reserve the right to change technical specifications at any time.

To purchase, please contact Summit Research at 831-226-2948 or by eMail. Items ship 1-3 days after orders have been processed unless otherwise specified. Price does not include shipping and will be included in your final estimate before processing.

To purchase, please contact Summit Research at 831-226-2948 or by eMail. Items ship 1-3 days after orders have been processed unless otherwise specified. Price does not include shipping and will be included in your final estimate before processing. -

-

$14,285.00

Polyscience 3HP Heavy Duty Durachill will handle numerous tasks. Air cooled with simple operation and maintenance. When precision liquid cooling matters, go with Polyscience cooling solutions.To purchase, please contact Summit Research at 831-226-2948 or by eMail. Items ship 1-3 days after orders have been processed unless otherwise specified. Price does not include shipping and will be included in your final estimate before processing.- DuraChill® Chillers 2HP and up are not available outside of the United States

- High capacity cooling for plasma torch cutting, machine tool hydraulics, high powered lasers, and other high heat generating processes and equipment

- Displays temperature and pressure or flow rate simultaneously

- User-adjustable temperature, pressure, and flow rate alarms

- Simple operation and maintenance

- Wide variety of options available

-

$17,995.00

Polyscience 8HP Heavy Duty Air Cooled 3 Phase Chiller will handle different tasks - 50L roto rating. When precision liquid cooling matters, go with Polyscience cooling solutions.To purchase, please contact Summit Research at 831-226-2948 or by eMail. Items ship 1-3 days after orders have been processed unless otherwise specified. Price does not include shipping and will be included in your final estimate before processing.- DuraChill® Chillers 2HP and up are not available outside of the United States

- High capacity cooling for plasma torch cutting, machine tool hydraulics, high powered lasers, and other high heat generating processes and equipment

- Displays temperature and pressure or flow rate simultaneously

- User-adjustable temperature, pressure, and flow rate alarms

- Simple operation and maintenance

- Wide variety of options available

-

$14,095.00

Specifications- Type of Product: Scroll Pump

- Manufacturer: Edwards

- Condition: New

- Part Number: A73001983

- Inlet: KF40

- Exhaust: KF25

- Motor: 1 Phase, 100-120/200-230V, 50/60Hz

- Pumping speed: 21 CFM

- Ultimate vacuum: 8 x 10-3 Torr

- Weight: 105 lbs

- closed loop temperature monitoring

- dry, clean vacuum free of lubricants

- simple, single-sided scroll design

- patented isolated bearing shield

- world-wide voltage compatibility

- low power consumption

- controllable gas ballast

- inverter driven motor

-

$7,117.00

Specifications- Manufacturer: Agilent

- Condition: New

- Part Number: IDP3B01

- Inlet: KF25

- Exhaust: KF16

- Motor: 1 Phase, 100-115/220-230V, 50/60Hz

- Pumping speed: 7.53 CFM (50Hz), 9.06 CFM (60Hz)

- Ultimate pressure: 1 x 10-2 Torr

- Weight: 75 lbs

- Low noise and vibration.

- Oil-free and contamination-free.

- High pumping speed provides rapid pump down and high gas throughput.

- Very low base pressure ensures optimal turbo pump performance with increased system reliability.

- IDP Pumps fully isolate the bearings and motor from the vacuum space and contain all pumped gases.

- Scroll pump technology’s long service interval results in low cost of ownership.

- Easy to integrate: minimal burden on system utilities& suitable for use inside cabinet enclosures.

- IDP Pumps are lighter than mechanical rotary vane and membrane pumps of similar pumping speed.

-

$5,490.00

Specifications- Manufacturer: Agilent

- Condition: New

- Part Number: IDP3B01

- Inlet: KF25

- Exhaust: KF16

- Motor: 1 Phase, 100-120/200-240V, 50/60Hz

- Low noise and vibration.

- Oil-free and contamination-free.

- High pumping speed provides rapid pump down and high gas throughput.

- Very low base pressure ensures optimal turbo pump performance with increased system reliability.

- IDP Pumps fully isolate the bearings and motor from the vacuum space and contain all pumped gases.

- Scroll pump technology’s long service interval results in low cost of ownership.

- Easy to integrate: minimal burden on system utilities& suitable for use inside cabinet enclosures.

- IDP Pumps are lighter than mechanical rotary vane and membrane pumps of similar pumping speed.

-

$5,164.00

Specifications- Manufacturer: Agilent

- Condition: New

- Part Number: IDP3B01

- Inlet: KF25

- Exhaust: KF16

- Motor: 1 Phase, 100-120/200-240V, 50/60Hz

- Pumping speed: 4.23 CFM (50Hz), 5.35 CFM (60Hz)

- Ultimate pressure: 3 x 10-2 Torr (50Hz), 2 x 10-2 Torr (60Hz)

- Weight: 54 lbs

- Low noise and vibration.

- Oil-free and contamination-free.

- High pumping speed provides rapid pump down and high gas throughput.

- Very low base pressure ensures optimal turbo pump performance with increased system reliability.

- IDP Pumps fully isolate the bearings and motor from the vacuum space and contain all pumped gases.

- Scroll pump technology’s long service interval results in low cost of ownership.

- Easy to integrate: minimal burden on system utilities& suitable for use inside cabinet enclosures.

- IDP Pumps are lighter than mechanical rotary vane and membrane pumps of similar pumping speed.