SPD-7 USPD

The Concept

A few years ago, a vision at Summit Research was realized that not all short path distillation was sufficient for every process. The distillation industry’s brainchild went to work to develop a multi process method with hardware arrangements that further added scientific tools to a processing technician’s arsenal.

Elliot Kremerman brought both this new theory and method of operating a short path in ways that had previously not existed in the industry; by releasing Ultra Short Path Distillation (USPD). Prior to the patents released, Elliot worked extensively on research and development partnering with highly regarded labs in the industry. This ensured the systems abilities were at the level customers expect from Summit Research.

One of the USPD’s novel technology consists of a revolutionary concept which was initially developed years before during Modified Path Distillation (MPD) developments. This is Elliot’s invention of placing a distillation head or principle portions within the flask itself. This allows the closest, and ultimately least rejective method to be applied with this design and utility application.

The System

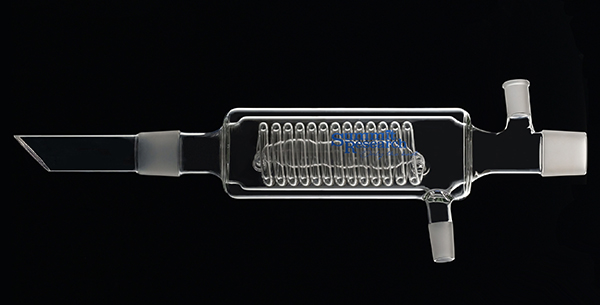

The head begins inside the flask and then transitions to a unique first of its kind condensing arm that is directly handling and condensing molecules in a mean free pathway. Earlier patented technology by Elliot will show where the next concepts follow.

There is a short style coiled (CT-USPD Triple Coil) trap directly after the primary condensing arm which behaves in the process like the previously patented “coil laminar” connection that Elliot Kremerman developed years ago. This isn’t exactly a cold trap, it’s more like a laminar flow portion of the SPD-7, similar to other laminar devices that create a mass in the flow pathway that reduces the initial turbulent and scattered vapor flow.

During operation the short coil cold trap in the utility design can be run at – 40c or lower, and all the way to 125-175c for hot pass processes. This is why this innovation isn’t seen just as a trap that protects the pumps, but rather a device that prepares vapors by either “trapping” them or just removing the initial heat load from the vapor stream.

The next two cold traps in Summit’s series displayed are the Summit research Inverted Cup Cold Trap, which was also patented by Elliot. There are two fashions for the cold traps. One is short, to rip off the initial temperature and begin dry vacuum operation. The second, is stacked and fully performs dry vacuum operation. These monolithic upside down cup trap vortices with the bung core which extends into the cup. This allows for an extremely effective maintenance of dry vacuum in a highly laminar system like the SPD-7.

So the question has always stood, what processes can this revolutionary technology be used for? Here we will begin the talking points on why this was created, and with what SOPs to match to achieve the highest repeatable success rate. Early on Elliot had envisioned a system to perform with a slightly different end result. But nevertheless, the development and production and implementation of this hardware has shown the following production benefits.

The Process

One very important point is that this product has been historically tainted by low end producers in an effort to profit, but also achieve the same results this machine is capable of. Here is a great example of a technician’s utility using the SPD-7 in their lab.

If a lab is producing a large amount of crystal/terpene rich product; in which dispensed portions allow an extraordinary surplus afterward of non active compound of rich slurry and sauces, which will consist of mostly terpenes and then dissolved non psychoactive compounds with healthy amounts of active compounds that can no longer be further crystallized.

The technician would place his left over slurry into the SPD-7 with all three trapping devices and condensing arm attached to a controlled diaphragm vacuum pump.

Absolutely pure and refined terpenes can be completely removed with unmatched clarity and aromatic values. With very cold temperature set by the user, the first condensing arm will essentially collect the terpenes with amazing purity and concentration of all desired aromatics. The short coil cold trap, when set with proper SOP (Standard Operating Procedure) will collect the 1% of rejected material that bounces out of the first condensing arm and the remainder of the hydrocarbon solvent used in the original fresh frozen high terpene and potency extract procedure. This is to be discarded since the original collected condensed terpenes are the targeted fraction. This is where the road map makes many options and turns available to the user.

Once the terpenes are collected, the receiving flask may be swapped allowing the user to immediately distill out the inactive compounds like waxes, fats, unwanted products etc – then with swing arm processes or glass swaps, the technician can dive right into their target compound distillation. The other option is, stop the process right after the terpene strip, then empty the system into a larger batch and go straight into remediation at a larger scale. This will allow the technician or user to actually perform a refinement and purification process. Reloading the machine with this refined and cleaner product will essentially pull a purer, cleaner, lower temperature fraction without worrying about distilling fats, lipids, waxes etc. that have otherwise been already removed via dewaxing, water washing, and column work performed prior to reloading the SPD-7.

The amazing ability of this process mentioned allows technicians to extract surplus terpenes from their product. Harvesting pure and mirror aromatics to the original extract they had, now into-bulk semi single sourced terpenes.

The machine would in theory further refine distillate and make available feedstock to be mixed with these batched terpenes. The technician would take volumes of distillate or any product and mix terpenes in a perfect combination and apply it in their product or vape carts. What’s important to understand is how much refinement this system allows to provide onsite options for vape pen production with top of the line materials made on site with users proprietary SOPs they harness this incredible technology and low cost production abilities.

Usage

Production, even at low to high scale with the SPD-7, was designed to operate with refined feedstock. Prior refinement procedures will include dewaxing, water washes, chromatography column work and even neutralizing washes. Although virgin feedstock can be processed the more volatile and lesser “held back” molecules will jump out of the system, while at higher temperature distillations the technician must remember there is near zero selectivity and other traditional short path heads like the FC Series or MPD Series would be more effective selection. This head accelerates the pre-processed feedstock operations. The highest useage we’ve seen is remediated solutions. Anything that has been stripped and refined to a higher potency and purity will launch downstream the SPD-7 system at much much lower temperature and faster speeds. Degradation is inherently reduced and so are boiling over conversions. Although this system can also be used with isomerized solutions, Summit Research has stayed away from recommending them used with media loaded flasks. It has been reported they can be used with media loaded flasks but we know as the creators of the USPD Systems that there isn’t anything being held back at the entry point of the head.